SUE - for demanding customers who want a reliable long-term partner within the field of TURNING / MILLING / DRILLING SUE offers a rapid metal CNC machining service for custom production of your prototype parts, unit parts, or small series (from 1 to 100+ parts). Our capabilities allow us to produce your functional metal parts very quickly in as little as one working day. This precision process is the best choice for prototyping and rapid production of small and large metal parts. You receive high dimensional precision parts made from a wide choice of ‘right materials’: aluminum machining, steel machining, stainless-steel machining, brass machining, etc.

10000+ Delivered

100+ Employees

18+ years of work

1000 ㎡

To provide best products and services to enrich costumers experience with profitable operations.

To add accuracy to our work by dedication, honesty and equality towards quality. To amalgamate like minded people for the progress of Enterprise.

To add niche products, services and technology based on need of our valued customers and the industry requirements. To provide high quality services and meet customer expectations at all levels.

Depending on the machining operation being performed, the CNC machining process employs a variety of CNC machines and machine tools to produce the custom-designed part or product. While the equipment may vary in other ways from operation to operation and application to application, the integration of computer numerical control components and software (as outlined above) remains consistent across all CNC machining equipment and processes.

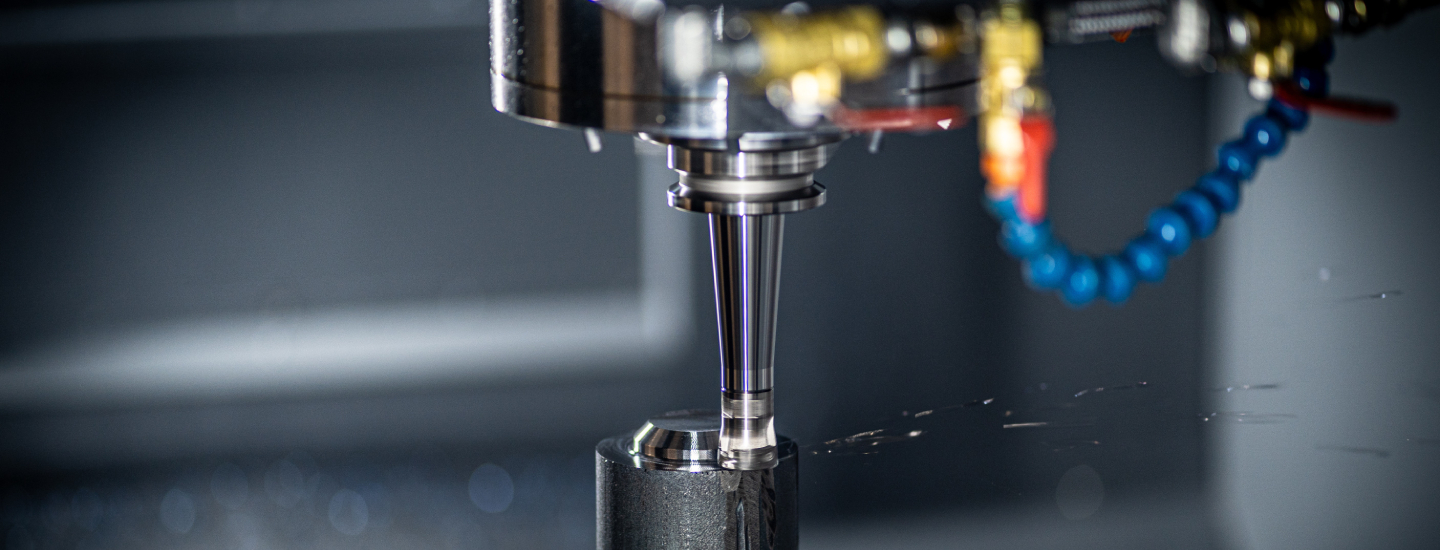

CNC milling is a process of cutting parts using a machine that performs the cuts with high accuracy and speed. The main application areas of CNC milling are in the aerospace, automotive, medical, and manufacturing industries. CNC mills have revolutionised the way parts are made. They can create parts with extremely high precision and quality.

Cold forging is a general term for various processes in which wire or bar material is formed into ready for assembly components. The benefits of this process: components are resistant to high temperatures and acids, are recyclable, their weight continues to decrease, and energy and material efficiency are high.

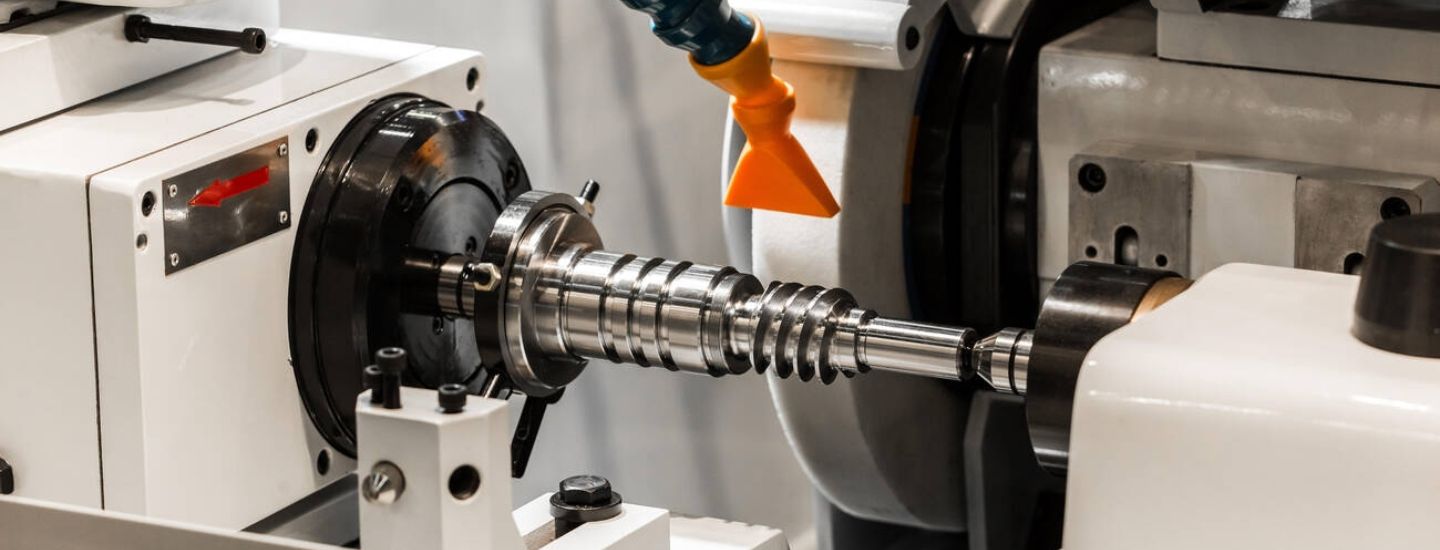

Turning tools come in two types — rough turning tools and finish turning tools. Rough turning tools allow you to remove large portions of materials rapidly and efficiently. This is possible because of its small clearance angle and ability to withstand high cutting pressures

Metal stamping is a relatively simple process where rolled or sheet metal, referred to as a blank, is placed in a press that has a die in the desired shape of the part. With force and compression, the die is pressed into the metal. After a predetermined amount of time, a partially completed part is removed.

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

~

~

~

~

The maintenance of a desired level of quality in a service or product,every stage of the process of delivery or production.

Customer Satisfaction is defined as a measurement that determines how happy customers are with a company's products.

Owing to our sound infrastructure, we can able produce products in bulk quantities and cater to the demands of numerous customers worldwide.

We are one of the leading players in this domain and have implemented innovative business strategies and modern techniques for our business.

Copywrite © 2023 Shree Umiya Enterprise

Managed By Adjoint Infocom Private Limited